Have you spent years mastering the art of string playing but still know little about the ideal way to handle your tools? Are you curious to learn more about the possibilities a high-performance string offers and do you want to optimize your performance in a few simple steps? Stringtelligence offers you an exclusive insight into the science of strings. Find widely unknown tips and tricks of the trade to perfect your sound and elevate your playing to an unexpected level! More than 20,000 words and 19 video tutorials in over 90 chapters: This is string know-how at its best!

What should I know about the E-string? The formula

In principle, there are three types of E-strings: wound, unwound and plated.

Unwound and plated E-strings

The core materials for unwound E-strings are either chromium-nickel steel or carbon steel. Our E-strings with a carbon steel core are tin-plated. To avoid corrosion, Thomastik-Infeld normally incorporates one or more protective metal layers as well. These strings are so-called multi-layer strings. Chromium-nickel steel is also referred to as chromium steel, non-corroding steel or simply stainless steel. Although chromium-nickel steel contains nickel and chrome among other substances, almost no allergies are triggered by this material. Chromium steel strings are extremely resistant to corrosion and can also be used without any plating for this reason.

If they are plated, in order to define sound or handling characteristics, gold, platinum, titanium and molybdenum are used as the outer material. Platings made of palladium and rhodium are also possible. These surface materials are very often used for jewelry.

Wound E-strings

Wound E-strings normally have a carbon steel core. The core is wound with thin flat strips of chromium steel, titanium or aluminum. The winding makes the string sound darker, improves the bow response, changes the torsion rigidity and therefore also prevents whistling.

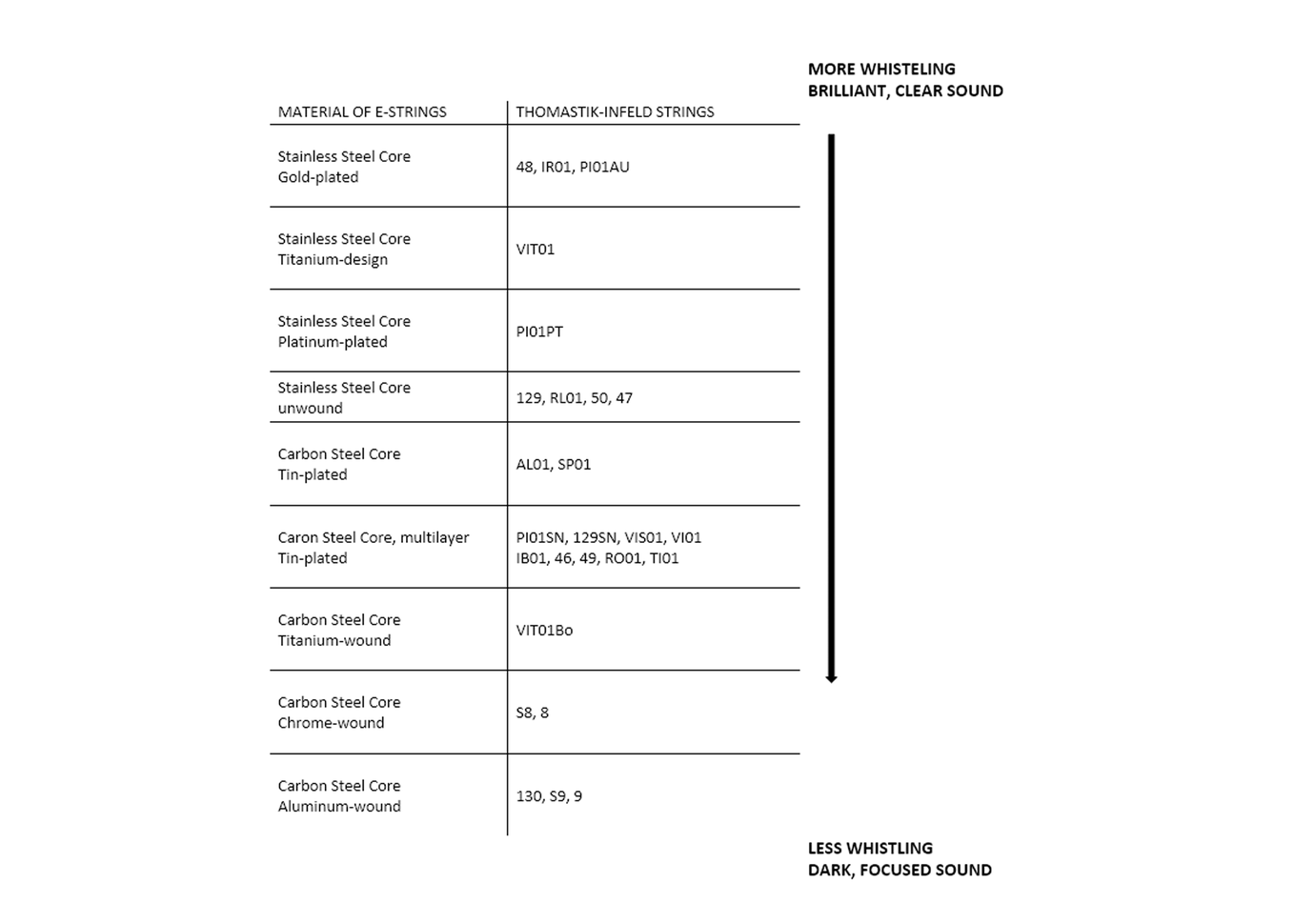

Different materials have different effects on the sound and whistling of the E-string. The following graphic shows which E-strings are characterized by a brilliant & clear sound, which ones whistle less and which sound darker & more focused:

Common E-string problems are:

- the whistling

- fifth impurity and corrosion

- the clanking

- excessive snapping of the E-string

BACK

ESPAÑOL

ESPAÑOL